Source: sunrise-metal.com

Laser engraving is a process that uses lasers to carve text, images, or patterns into various materials. It’s a versatile tool that can be used for a variety of purposes, from branding products to creating custom designs. In this article, we will explore what this is and how it works. We will also give you a few tips on how to use it to your advantage in your business. So read on to learn more about this versatile process!

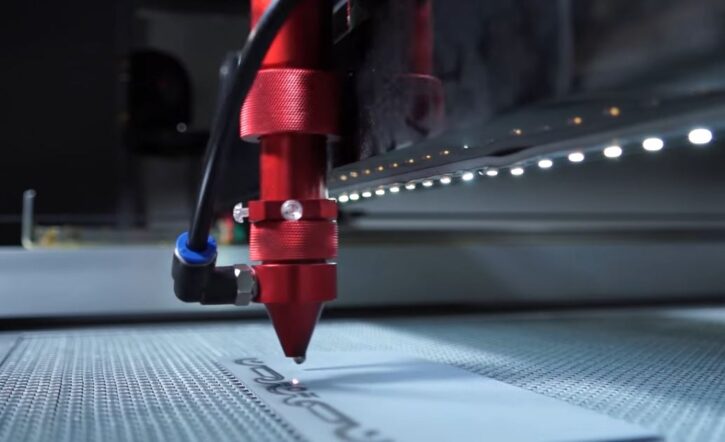

What is Laser Engraving?

Laser engraving is a process where a laser beam is used to cut intricate designs into metal or other materials. The design is first drawn out on the surface of the object to be engraved, and then the laser beam is used to carve the desired pattern into the metal. The process can produce beautiful, intricate designs that are difficult or impossible to achieve using other methods.

First, you’ll need to create your design in a computer program or on paper. Once you have a rough idea of what you want your engraving to look like, you can start cutting out the specific pieces using your machine. Keep in mind that your finished product will be much smaller than if you had created it using traditional methods such as carving or etching.

This is a complex and highly specialized process, so be sure to consult with an expert if you’re interested in trying it out yourself. It’s also worth noting that this type of engraving isn’t always suitable for all types of materials – check with your supplier before starting any projects!

How to Choose the Right Laser for Your Project?

There are a few things to consider when choosing a laser for your project. The power, the speed of the laser, and the type of material you’re working with are all important factors.

- Power: The power affects both how deep the etching can go as well as how quickly it can etch your material. For most small-scale projects, an 870 nm or 1064nm laser will be sufficient. If you’re looking to do detailed work or remove large amounts of material, you’ll want to look for a higher-power laser (like 1260 nm or 1495nm).

- Speed: The speed of the laser impacts how quickly your material can be engraved. Lasers that are faster will also be less likely to create unintended lines or scratches in your design. For most small-scale projects, a speed between 5 kHz and 10 kHz will be fine. If you’re looking to do detailed work or remove large amounts of material quickly, consider looking for lasers that reach speeds above 20 kHz.

- Type of material: Different lasers work best on different types of materials. Lasing materials like plastics and glass will generally respond well to lasers with shorter wavelengths (like 635 nm or 808 nm).

Conclusion

If you are looking to add a special touch to your custom apparel or furniture, laser engraving may be the perfect option for you. With this technology, you can easily etch text or designs into any hard surface. This is a popular option for weddings, birthdays, and other special events where attendees can personalize their outfits or furniture with unique symbols and messages. If you’re interested in trying laser engraving for yourself, be sure to consult with an experienced provider who can explain the process in detail and guide you through the many customization options available.