Source: amadaweldtech.com

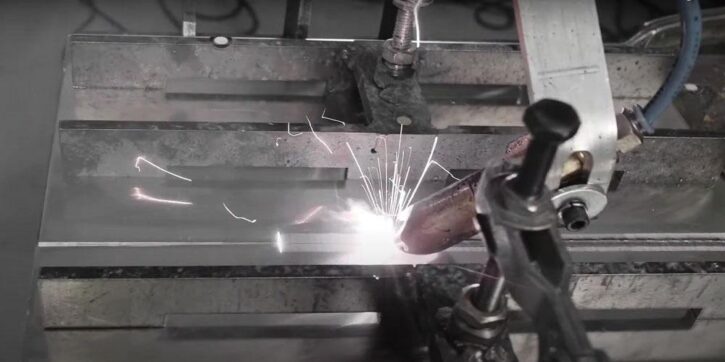

The laser cleaning process is one of the most powerful and versatile tools in the industrial cleaning arsenal. It’s capable of removing a wide variety of contaminants from a variety of surfaces, making it a key tool for any company that relies on cleanliness as part of their operations.

In this blog post, we will provide you with tips to help you understand this process better. We’ll cover topics like what lasers are used for, how they work, and some common complications that can occur during the process. By understanding the basics of it, you will be able to optimize its use in your business and achieve the results you need.

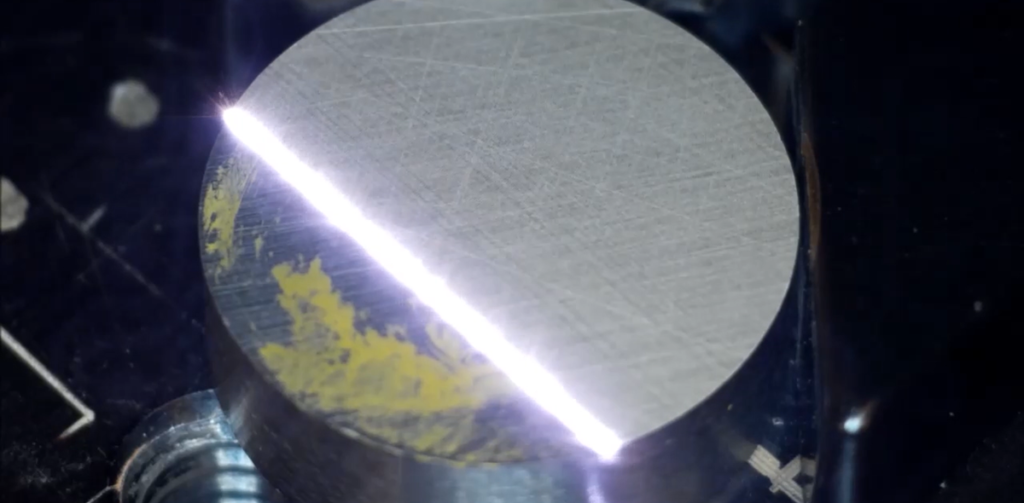

What is a Laser Cleaning Process?

A laser is powered by a light source and used to heat up the surface that needs to be cleaned. This heat then causes the contaminants to break down and be removed from the surface. When it comes to the laser cleaning process, the most important part is to choose the right laser for the job. There are different types that can be used for different purposes, but all of them share the same basic process.

- First, you need to determine what kind of debris needs to be removed from the surface. This can include dirt, dust, grease, and even paint or other finishes.

- Once you have determined the type of contamination on the surface, you need to select a laser that is best suited for removing it. There are three main types of lasers: CO2, diode and solid state lasers. Each has its own properties that make it better suited for specific tasks.

- Once you have chosen your laser type and selected your target area, you will need to adjust some settings on your machine. The most important setting is power – too much power can damage the surface while too little power will not achieve the desired results. You also need to decide how long the laser should stay on the target area – too long and the surface will be burned, while too short a time and the contamination will be removed but with greater damage to the surface.

- Once you have set up your machine and chosen your power and time settings, all you need to do is hold down your trigger and wait for the machine to work its magic. As long as everything is properly set up and your laser is functioning properly, you should be able to clean any surface using a laser cleaning process.

Safety Tips for Going Through a Laser Cleaning Process

There are a few safety tips you should keep in mind when undergoing a laser cleaning process:

- Always wear protective eyewear and clothing. Even small particles of glass or other material can cause serious eye injuries if they enter your eyes during the cleaning process.

- Shield your skin from the laser beam with a piece of paper or cardboard. This will help prevent burns, skin irritation, and other potential problems.

- Keep the room clean and free of any objects that could interfere with the laser’s path or cause interference to other equipment in use.

- Use the correct power level for your laser device and lens (discuss this with your technician). Too much power can damage both the surface being cleaned and surrounding areas, while too little power can leave behind incomplete or patchy results.

Conclusion

We hope that our tips were helpful and that you now have a better understanding of what to expect during your appointment. If you have any questions or would like further information, don’t hesitate to contact us at any time. Thank you again for choosing us as your go-to source for all things laser-related!