Source: news.ewmfg.com

Investment casting is a manufacturing process that uses molds to create copies of objects. The molds are made from a variety of materials, including plastic, metal, and rubber. The process begins with a design that’s been created in 3D software. This design is then transferred to the molds, which are usually made out of metal or plastic. Once the molds have been customized to fit the object being cast, the process begins. molten metal is poured into the mold, and it cools and hardens around the object inside. This process creates a replica of the original object that can then be used for various purposes, such as jewelry, car parts, or even toys.

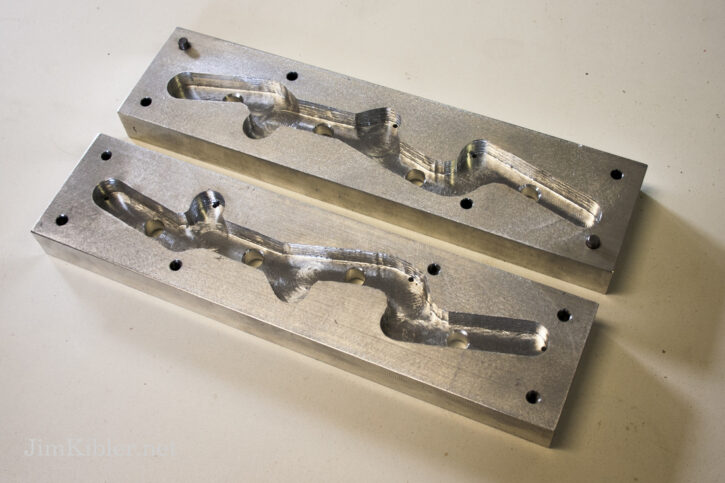

The investment casting process begins with the creation of the mold or pattern. This can be a simple design, such as a figurine, or it may be more complex, such as a car model. The pattern is then produced in several different materials, including metal, plastic, and plaster.

Investment Casting Process Steps

The investment casting process begins with a designer or artist concepting the object and then creating a 3D CAD model. This CAD model is used to create a wax model which is then used to create the final metal piece. This process can take many different steps, but each one plays an important role in creating a quality end product.

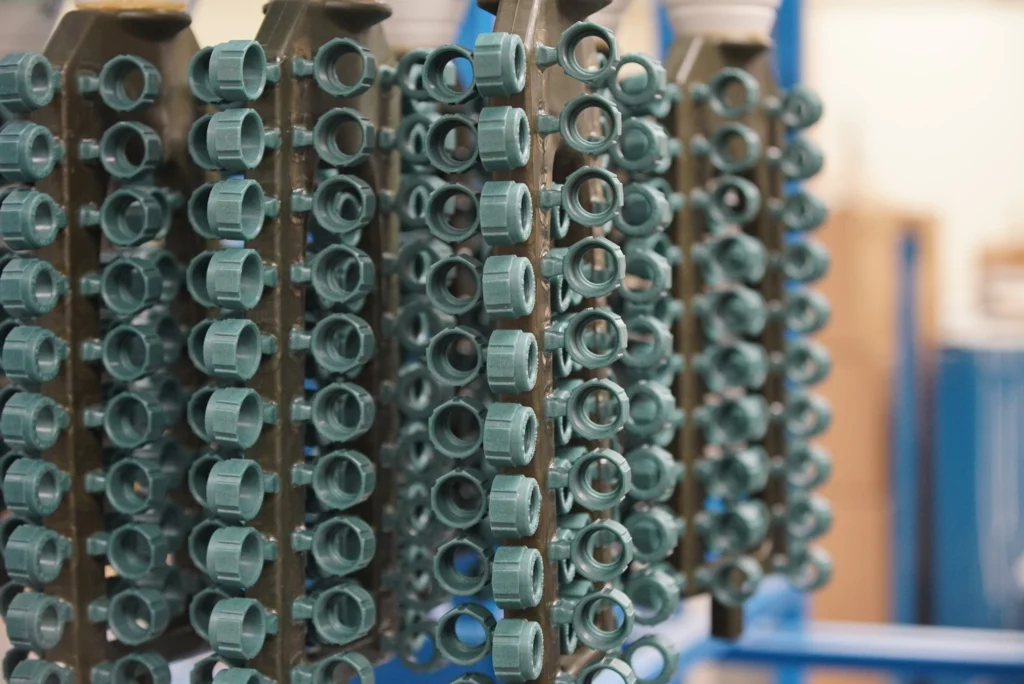

– The first step is to create a wax model of the object. This wax model is used to create the final metal piece, and it must be accurate in order for the finished product to look correct. The wax model is sculpted using tools such as modeling clay and sandpaper, and it must be precise in order for the finished product to look correct. If the wax model isn’t accurate, then the final metal piece won’t look correct either.

– The next step is to create a steel mold. This steel mold is used to make copies of the wax model, and it’s very important that it’s accurate. If the steel mold isn’t accurate, then the copies won’t be accurate either. Steel molds are often made using cold stamps, and they need to be perfectly formed in order to work correctly.

– The third step is called plating. This step involves coating the steel pieces with silver or other metals so that they will form a permanent bond with the wax. Plating is often done using a process called electroless nickel plating, and it’s very important that it’s done correctly in order for the finished product to look correct.

– The final step is to polish the metal pieces. Polishing is often done using a process called wet polishing, and it’s very important that it’s done correctly in order for the finished product to look correct. If the polishing isn’t done correctly, then the metal pieces will look dull and unappealing.

In conclusion, the investment casting process is very important in creating a quality end product. Each step must be done correctly in order for the finished product to look correct, and if any of these steps isn’t done correctly, then the final product won’t look correct.